River Rock Installation Instructions

General Tools and Materials:

-

Caulk Gun

Caulk Gun

-

Chalk Line / Laser

Chalk Line / Laser

-

Clean Cloth

Clean Cloth

-

Color Coordinating Textured Caulk

Color Coordinating Textured Caulk

-

Cotton Swabs

Cotton Swabs

-

Level

Level

-

Loctite© PL© Premium© 3X Construction Adhesive

Loctite© PL© Premium© 3X Construction Adhesive

-

Panels

Panels

-

Pencil

Pencil

-

Safety Glasses

Safety Glasses

-

Small Paint Brush

Small Paint Brush

-

T-square

T-square

-

Tack Cloth

Tack Cloth

-

Tape Measure

Tape Measure

-

Touchup Kit

Touchup Kit

-

Water

Water

-

Wood Cutting Saw with Finish Blade

Wood Cutting Saw with Finish Blade

(1) tube of textured caulk is typically needed for every (4) panels.

Installation-Specific Tools and Materials:

Adhesive and Fastener Installation

-

Deck Screws

Deck Screws

-

Drainage Mat (Exterior Installation only)

Drainage Mat (Exterior Installation only)

-

Screw Gun / Drill Driver & Driver Bits

Screw Gun / Drill Driver & Driver Bits

Adhesive-Only Installation Over Concrete/Masonry/Metal

-

Disposable Gloves

Disposable Gloves

-

Great Stuff

Applicator

Gun

Great Stuff

Applicator

Gun

-

Great Stuff Pro Gun Cleaner

Great Stuff Pro Gun Cleaner

-

Great Stuff Pro™ Construction Adhesive

Great Stuff Pro™ Construction Adhesive

Acclimate all panels by storing them flat in the installation location (but away from moisture and direct sunlight or other heat sources) for at least 24 hours.

WARNING:

- Be sure to obey all safety rules and recommendations set forth by tool manufacturers.

- Wear safety glasses during the entire installation process.

- Be sure to follow all applicable building codes.

- Always comply with clearances set forth by the manufacturer of stoves, fireplaces, furnaces, and any other heat source.

River Rock Installation

Before You Start

- Ensure wall is structurally sound and in good condition.

- Gather all tools and materials.

- For exterior Installation, install exterior sheathing and house wrap.

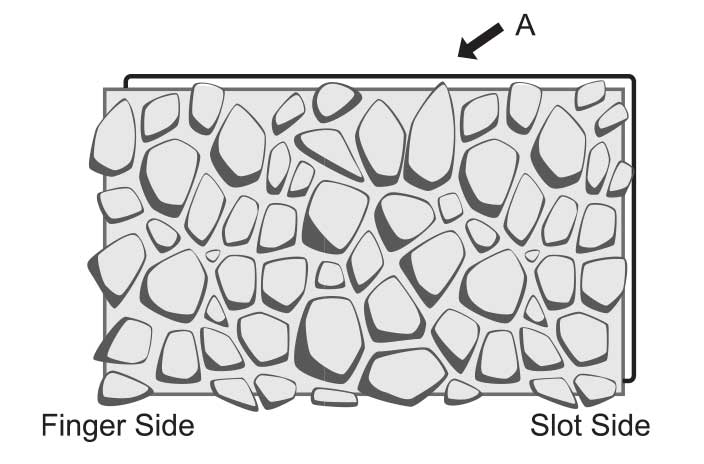

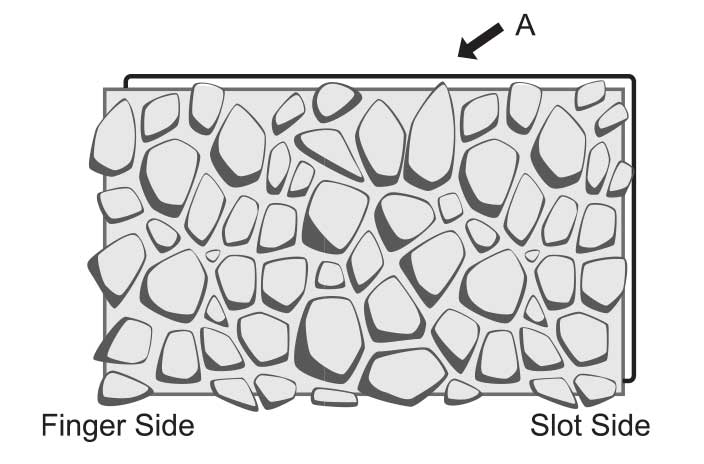

- Installation will run left to right. Orient one of your panels so that the flat lip on the long side (A) is up.

- If you will be working around corners, determine the best approach for your project using our installing faux panels around corners instruction sheet.

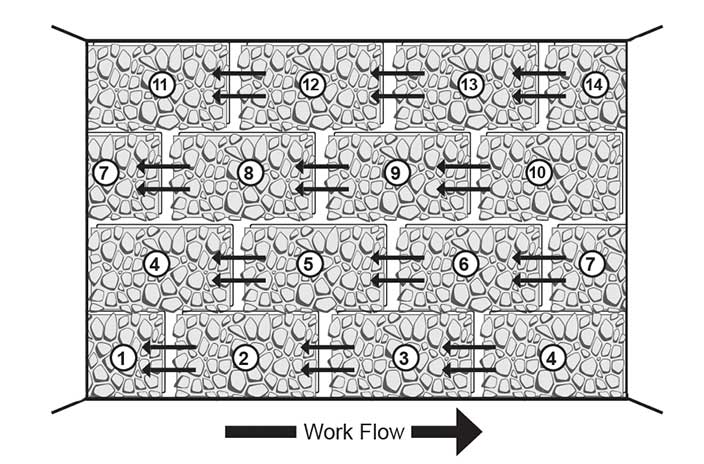

Left to Right Installation

Click Here for Care and Maintenance info.

Directions

Step 1

Install Drainage Mat (Exterior Only)

Tools:

- Drainage Mat

- Deck Screws

- Screw Gun/Drill Driver with Driver Bits

NOTE: Skip this step if installing with adhesive only method over concrete, masonry or metal.

- Orient the roll so that the grid side faces the wall and the smoother side faces out.

- Fasten the drainage mat to the wall using deck screws long enough to pass through the mat, house wrap and into the structural material.

- Please comply with all regional building codes. Drainage mats are required for all exterior installations except those over concrete/masonry/metal.

- The DM-3611R Drainage Mat meets Canadian Building Codes and is required for most exterior installations in Canada.

- Exterior sheathing and house wrap must be installed before the drainage mat.

Step 2

Orient Panels & Determine Installation Order

- Orient each of the panels so that the flat lip on the long side (A) is up.

- It is often helpful to establish an order for the panels by laying them out prior to starting the installation process. Look at the variation in color and texture to ensure no one section draws the eye.

- Since the rocks project lower than the body of the panel you will have to decide if you want to trim them to be flush with the bottom of the panel or allow them to project. Do not rotate the panel so that the rocks project up because you will lose the shiplap joint between panels, leaving them vulnerable to water penetration.

Step 3

Trim Panels

Tools:

- Pencil

- Tape Measure

- T-square

- Wood Cutting Saw with Finish Blade

NOTE: Skip if installing interlocking corners

- If trimming the bottom of the first row of panels, determine the number of panels needed to run the length of the first row. If using a corner be sure to include it in your measurement.

- If the width of your installation requires using a partial panel and/or mitering a corner, you will want to use the River Rock Grouted Filler Panel and Rock Set (both sold separately) as part of your installation.

- Trim the bottom off panels/corner needed for the first row.

- Trim the fingers off the first panel.

Step 4

Prepare Surfaces

Tools:

- Clean Cloth

- Tack Cloth

- Wipe hard surfaces with a wire brush to remove loose debris

- Wipe walls with a tack cloth to remove any dirt or sawdust.

- Clean surfaces are required to ensure the panels adhere properly.

Step 5

Draw Level Line

Tools:

- Pencil

- Level / Laser Level

- Chalk Line / Laser

Find the high point on the floor/ ground using a level. Place a full size panel against the wall and mark the height. Draw a level line the length of the wall.

Step 6a

Attach Panel to Wall

Adhesive & Fastener Installation:

Tools:

- Deck Screws

- Screw Gun / Drill Driver & Driver Bits

- Level / Laser Level

- Tack Cloth

Do NOT over tighten screws.

Step 6b

Attach Panel to Wall

Adhesive-only Installation over Concrete/Masonry/

Metal:

Tools:

- Great Stuff Applicator Gun

- Great Stuff Pro™ Construction Adhesive

- Disposable Gloves

Step 7

Repeat for the Length of the Installation

Tools:

- Clean cloth

- Caulk Gun

- Color Coordinating Textured Caulk

- Loctite PL 3x

- Butt the panels tightly together while following the level line. Dry fit each panel before applying adhesive to ensure it fits flush. Trim if necessary. The last panel on the row will have to be trimmed from the finger side of a panel.

- Add a bead of caulk to the lip of the panel where it meets the face.

- Add a bead of adhesive to the lip of the installed panel close to the edge.

- Attach the panel to the wall as described in Step 6.

- Use a damp cloth to remove any excess adhesive or caulk before it dries.

- If your installation requires a partial panel (typically when using two outside corners or mitering an inside corner), cut a grouted filler panel to width and use a router to trim the panel to maintain the integrity of the vertical shiplap joint. Use construction adhesive to adhere the individual rocks to the filler panel at the end of the installation.

Step 8

Start Next Row

Tools:

- Caulk Gun

- Wood Cutting Saw with Finish Blade

- Loctite PL 3x

- Pencil

- Chalk Line/ Laser

- Level

- Trim the fingers off the first panel so that it sits flush against the wall and the rocks fit with the gaps in the panel below.

- Apply a bead of adhesive to the top lip of the installed row of panels.

- Repeat Steps 6 to 8.

Step 9

Touch-Up As Needed

Tools:

- Water

- Touch-up Kit

- Paint Brush

- Clean Cloth

- Cotton Swabs

- Caulk Gun

- Color Coordinating Textured Caulk

- Loctite PL 3X

- If filler panels were used, add individual rocks to the filler panels using Loctite PL 3x. Use painters tape or finish nails to hold the individual rocks in place while the adhesive dries.

- Add a bead of caulk to seal any mitered joints and where a panel butts against another surface (like an adjoining wall).

- Add caulk to fill in voids, gaps and holes from screw heads. Carefully blend before it dries.

- If your touch-up kit contains a base coat, use a cotton swab to apply a light layer of the base coat and allow it to dry completely (about 30 minutes).

- Using a paint brush, apply the appropriate paint then dab with a soft cloth to blend and allow to dry completely (about 30 minutes).

- If your touch-up kit contains a wash, apply the wash using a paint brush and dab with a soft cloth to blend. If the bottle is labeled “wash concentrate” add tap water to the neck of the bottle, screw the lid back on and shake to mix before using.

- If you need to mix colors to achieve the desired shade, we recommend doing so on a piece of scrap material.

- Paint can be thinned by adding water.

- Start with lighter colors